WP 2: Selection and characterisation of surfaces and coatings

State of the art in the field

A particular need is the need for quantification of biocompatibility as development of therapies is limited by the fact that currently fewer than ten materials are used as implantable materials within the body. Measurements for the properties of cells and proteins on surfaces are needed to quantify biocompatibility and elicit the understanding of the role that surface chemistry or topography has to cause adverse reactions such as inflammation or trigger the immune response. Biocompatibility, controlled by interactions between surfaces and the complex biochemistry of the body, is key to the effectiveness of an implanted medical product. A rigorous understanding of these interactions will enhance the design and development of reliable medical products and assist the development of new diagnostic and therapeutic methods. However, the metrology needed to support these scientific endeavours, including measurement techniques, data analysis methods and standard properties definitions required to characterise the complex spatial distribution of physical and chemical properties of surfaces and attached cells and proteins, is currently lacking. For example, in 3-D tissue scaffolds it is difficult to image cells within the construct with any degree of confidence, indeed the approach commonly utilised is to release the cells from the scaffold thereby losing spatial information.

A particular need is the need for quantification of biocompatibility as development of therapies is limited by the fact that currently fewer than ten materials are used as implantable materials within the body. Measurements for the properties of cells and proteins on surfaces are needed to quantify biocompatibility and elicit the understanding of the role that surface chemistry or topography has to cause adverse reactions such as inflammation or trigger the immune response. Biocompatibility, controlled by interactions between surfaces and the complex biochemistry of the body, is key to the effectiveness of an implanted medical product. A rigorous understanding of these interactions will enhance the design and development of reliable medical products and assist the development of new diagnostic and therapeutic methods. However, the metrology needed to support these scientific endeavours, including measurement techniques, data analysis methods and standard properties definitions required to characterise the complex spatial distribution of physical and chemical properties of surfaces and attached cells and proteins, is currently lacking. For example, in 3-D tissue scaffolds it is difficult to image cells within the construct with any degree of confidence, indeed the approach commonly utilised is to release the cells from the scaffold thereby losing spatial information.

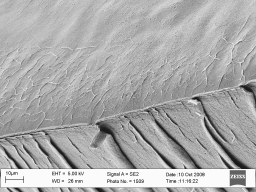

Any surface that comes into contact with body fluids will be coated in a layer of adsorbed proteins within a fraction of a second. Differences in binding affinity and protein mobility may result in some compositional changes in the adsorbed protein layer but these will be complete within a short timescale, much less than that required for cells to adhere to the surface. The response of cells to the protein coated layer may be adverse, triggering the immune response or positive, in the sense that the cells will adhere and spread forming contacts with adjacent cells. This behaviour is the basis of biocompatibility and is fundamental to the success of tissue scaffolds. It is an area that has been neglected in the field of tissue engineering due to the difficulty of characterising in 2D what are often very complex shapes. The lengthscale of the surfaces within tissue scaffolds is also typically much less than conventional surface analysis methods such as white light interferometry can accommodate, too soft for stylus-based instruments or too rough for techniques such as AFM. However progress can be made in deciding what the critical factors a surface needs to possess in order to be suitable for cells to adhere to and proliferate on by using 2D textured surfaces. These can be manufactured with controlled nano-scale or micrometer-scale features with controllable or at least known chemistries that will impact on both protein adsorption and cell attachment.

Movement beyond the current state of art

In this work package samples that will be used to explore the accuracy and limitations of the different imaging techniques will be produced. A set of control surfaces will be produced, beginning with commercially available polystyrene as used in cell cultureware, and distributed to project partners to use in the development and evaluation of techniques for characterising cell behaviour. These surfaces will be prepared with properties (e.g. morphology or chemistry) that induce changes in cell behaviour, permitting an evaluation of different imaging modalities to detect such changes and to identify suitable metrics for quantifying them. New methods for analysing and quantifying surface topography will be developed and applied to the surfaces in order to produce parameters for 3-D morphology that are meaningful for correlation with biocompatibility experiments. Measurements of protein adsorption and conformation on the surfaces will be carried out to provide an understanding of the effect of the micro/nano-texture on protein attachment. Control samples with defined 3D structure will be created for the assessment of depth profiling capability of imaging and spectroscopic mapping techniques in other WPs. For example gel coated surfaces with different thickness can be used to fix cells at different depths. Gel coatings can be doped with known levels of fluorophore, scattering entities or simply adding colour (phenol) in a culture medium such as DMEM (Dulbecco's Modified Eagle's Medium) or altered through changes in the cross-link density and or type of gel. This will enable the effects that radiation absorption or scattering have on the accuracy of the images to be ascertained. There will be metrological and experimental challenges to overcome following this approach, particularly in casting uniformly thick gels and in preventing dehydration from occurring and ensuring that any dopant or scattering entities are uniformly distributed.

Scientific tasks

Agree common sample requirements for partners Source materials needed for manufacture of control surfaces Prepare surfaces by coating, physical or chemical treatment Characterise surfaces and develop meaningful parameters for quantifying texture Carry out protein absorption experiments Develop techniques for preparing samples with controlled 3D structure Document techniques and pass on knowledge to partners

Technical risks

The range of potential factors affecting biocompatibility is potentially so large that information obtained from characterisation techniques is too complex to interpret in a useful way. Statistical design of experiments and other modelling approaches will be used to elicit useful conclusions

Expected outputs

Characterised surfaces for use in the project Protocols for producing control samples for developing metrology for biocompatibility and cell behaviour Assessment of proteins on surfaces reported in a scientific paper

Selected references

[1] E James, LI Mikhalovska, PE Tomlins, F Paul & SV Mikhalovsky, Real-time monitoring of cellular integration into bulk soft tissues scaffold materials, Journal of Materials Chemistry 13, 654-656, 2003

[2] P.E. Tomlins, P. Grant, L. Mikhalovska, S. James and S. Mikhalovsky, Measurement of Pore Size and Porosity of Tissue Scaffolds, Computer Methods in Biomechanics & Biomedical Engineering - 5, Feb 2005

For more information: Dr. Paul Tomlins