THERMO Metrology for Thermal Protection Materials (EMRP SIB52 Thermo)

The Project

Download poster for more information

Challenges - Step changes in metrology

Recent developments in thermal protection systems have the potential to provide performance that is several-fold better than conventional insulation materials, but there is currently no reliable metrology framework with which to validate their use in safety critical engineering.

- Mandatory EU regulations (EU NO. 305/2011) require thermal performance measurements that are three times better than the current level of agreement between national reference laboratories.

- Advanced manufacturing industries cannot reliably select or develop materials for applications at high temperatures, as existing industrial measurement techniques have shown a significant level of scatter, sometimes over 100 %. This leads to costly overengineering or the potential for higher risk of industrial disasters/incidents.

- Large gaps in the underpinning scientific knowledge within European measurement standards are preventing reference laboratories from meeting ever more stringent requirements from industry. These metrological and material issues relate to complex heat transfer through porous materials; experimental validation of theoretical and numerical radiative heat transfer models; temperature sensor degradations; quantifying surface thermal contact; new advanced material and high emissivity coatings.

Approach - Chain of traceability to SI units

Establish a complete traceability chain for characterising thermal performance of advanced thermal protection materials.

Achieve three times better European equivalence and evaluate the viability for improving industrial measurement techniques up to 800°C.

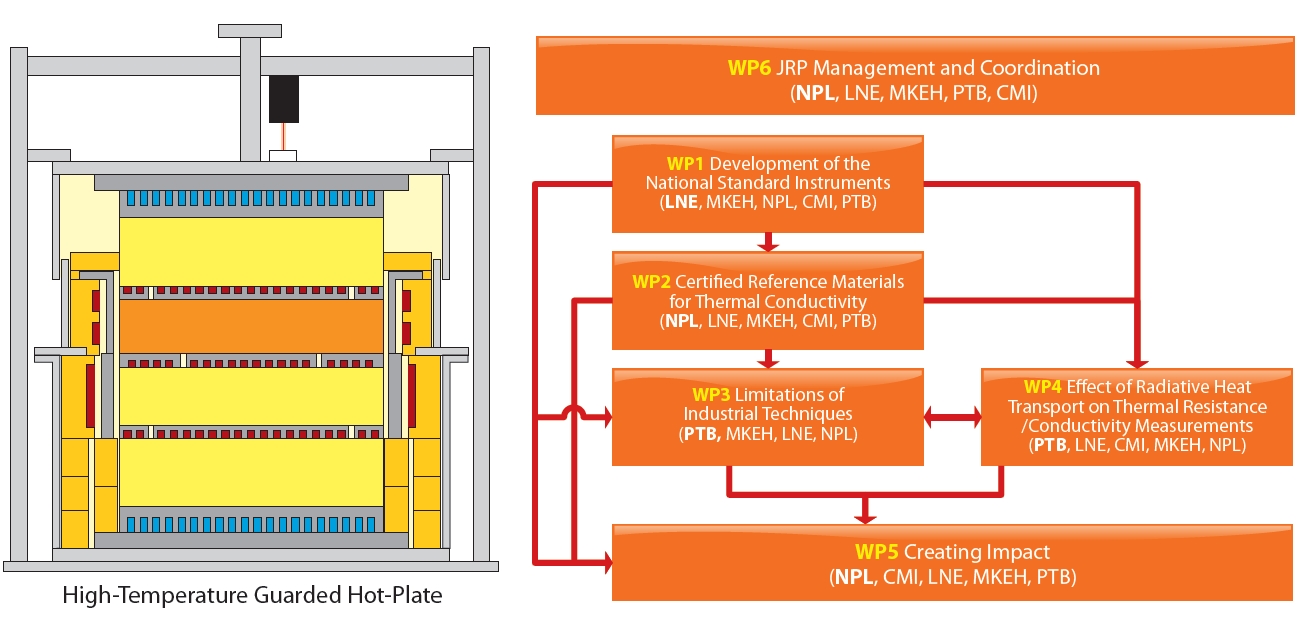

Consortium: This project combines the distinct expertise from leading national research programmes to find integrated solutions to thermal metrology and traceability challenges.

WP1: Development of techniques for a next generation National Standard Instruments with step-change in performance, including thin temperature sensors for surface temperature measurements, high emissivity coatings, thermal contact resistance issues and thermal guarding systems (SRT-s21 objective No. 2 and 3)

WP2: First reference materials with thermal conductivity in the range 0.02 W•m-1 K-1 to 1 W•m-1•K -1 and covering temperatures up to 800°C, which will be an essential tool for investigating the causes of disagreement (SRT-s21 objective No. 5)

WP3: The first time that world-leading experts in different thermophysical measurement techniques will work together to develop impartial recommendations on the limitations and viability of using transient and other industrial techniques (SRT-s21 objective No. 4)

WP4: Investigation of radiative heat transport effects on thermal conductivity measurements using a combination of theoretical, numerical and experimental approaches, including determination of appropriate levels of tolerance for thermal conductivity measurement apparatus (SRT-s21 objective No. 1)

WP5: Creating Impact

- The output of this JRP will be provided to CEN TC 89 for finalising a new European measurement standard EN/TS 15548-1 and also support the work of BIPM CCT WG9 (key-comparison), Euramet TC-TP, CEN TC 127 and ISO TC92.

- JRP website, 2 workshops at key conferences, 10 peer-reviewed papers, and 5 Good Practice Guides.

- Dissemination will be driven by the Stakeholder Committee (also project collaborators).

Impact - Mandatory EU regulations

Direct impact

- The output of the project will immediately provide the metrology that is urgently needed to implement new European regulations (EU NO. 305/2011) in the form of mandatory EN product standards (EN 14303 to EN 14309, EN 14313 and EN 14314).

- Allow European manufacturers to meet the mandatory CE marking requirements and market their high-temperature insulation products. The global high-temperature insulation product market was €2.2B in 2011 and Europe is the largest consumer of products with 39% market share.

- Help instrument manufacturers to develop and market commercial equipment that is needed to meet growing industrial demand for measurements.

- Increase the capability and the capacity of thermal conductivity metrology within Europe. The funded partners will become the core of a European measurement infrastructure providing traceability for thermal conductivity.

Financial impact

Due to the broad range of applications and industries, the full extent of the financial impact is huge and impossible to estimate reliably, but the following examples highlight the stakes:

- High-performance thin light-weight thermal protection composites are an essential technology for reducing aircraft weight and emissions. Fines for aircraft operators not meeting the EU Emission Trading Scheme will be between €4.5 M to €19 M per aircraft.

- Netherlands Centre for Technical Insulation suggests that European refineries could be €3.5 billion/year more competitive if the current levels of insulation were rectified.

Social impact

- Enable the designers of fire engineering (Structural Eurocodes EN 1990 to EN 1999) and transportation safety systems to select the best performance thermal protection materials, thereby reducing the rate of industrial disasters/incidents and saving lives.

- Enable the uptake of innovative thermal protection systems, which in turn support implementation of many Key Enabling Technologies.

For more information please contact: Jiyu Wu