The Project

Overall Objective

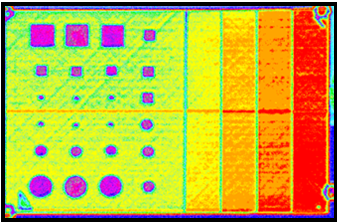

Project VITCEA will encourage industry adoption and the realisation of promising NDE techniques, such as microwave, active thermography, laser shearography and phased array/air-coupled ultrasonics, thus enabling the increased use of FRPs for energy applications. This will be achieved through the provision of operational procedures based on the comprehensive evaluation and development of each technique for detecting a range of defects typical to FRP composites that are used in wind, wave, tidal, oil and gas and transport sectors.

Timescale

The VITCEA project runs from July 2014 to June 2017.

Project Summary

A summary of the project is available here

Key Scientific and Technical Objectives

The four main objectives of the JRP are:

- To design and manufacture suitable natural and artificial reference defect artefacts representative of the materials and defects typically found in, and of concern to, the renewable energy (wind, wave, and tidal), oil and gas and transport sectors,

- To develop operational procedures, drafted in the style of CEN and ISO standards, for: microwave; active thermography; laser shearography, and phased array ultrasonic techniques. The specific metrology objectives are to:

- Establish the limits of detection for each NDE technique,

- Develop analytical techniques for accurately sizing defects for the different NDE techniques. The NDE results will be compared with independent characterisation techniques,

- Compare the merits of each NDE technique for different defect types found in a broad range of composite material systems using an objective probability of detection (POD) benchmarking framework.

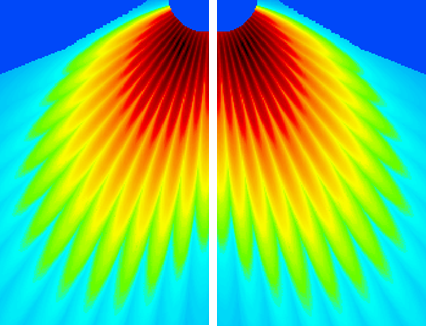

- Advance the theoretical simulation of the inspection techniques in particular taking into account the intrinsic anisotropic nature of composites and their constituents,

- To evaluate the POD methodology, based on modelling simulations with the aim of reducing the cost and time requirements of intensive experimental POD trials,

- To validate and refine operational procedures via intercomparison exercises and field trials in collaboration with organisations from the renewable energy (wind, wave and tidal), oil and gas and transport sector supply chains. Defect artefacts will be inspected using the developed operational procedures.

Advancing the state-of-the-art

- Development of novel defect manufacturing methods and production of energy sector specific reference defect artefacts

- Formulation and validation of operational procedures for novel NDI techniques applied to FRPs,

- Development of novel measurement techniques for characterising underpinning material properties

- Development of NDI technique specific data reconstruction and signal processing methods for defect sizing

- Development of predictive models simulating defect detection

- Theoretical POD assessments for FRPs using novel NDI techniques

- Generation of comparative experimental and theoretical POD data