Work Packages

Workpackage 1:

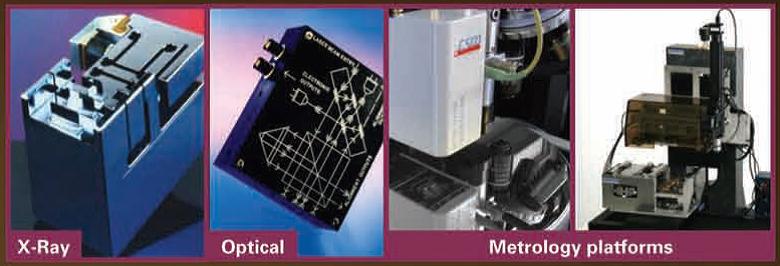

This workpackage will traceably characterise the displacement drift of the indentation metrology platforms. Dimensional traceability will be linked to NPL's X-ray interferometer (XRI) using an optical interferometer (as the transfer standard). A plane mirror differential Jamin optical interferometer will be upgraded to use Field-programmable Gate Array (FPGA)-based low noise electronics.

An X-ray Interferometer will be used to perform a primary comparison of the stability and drift of the Jamin interferometer. The optical interferometer will then be used to characterise the dimensional drift of materials commonly used in metrology platforms and to characterise the actual drift and environmental sensitivity of a range of Instrumented Indentation Test (IIT) systems.

Workpackage 2:

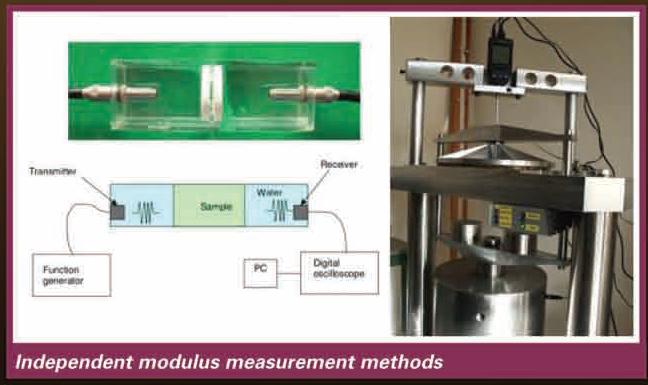

In this workpackage measurements will be performed on a range of industrially relevant metallic and viscous materials using three instrumented indentation instruments covering different contact sizes and force ranges. Mechanical property measurements will be made of the time-dependent properties of seven research grade polymers, spanning a range of viscous properties, using both oscillating and quasi-static indentation based methods as well as from independent measurements using bulk dynamic mechanical analysis and uniaxial creep.

The data generated will allow three key issues to be addressed:

- Identify the optimum test procedures for measuring time-dependent properties (creep, viscosity, loss and storage modulus).

- Develop an uncertainty budget that identifies the sensitivity of the measurement results to environmental and protocol variation.

- Establish the effect different volumes of material in different stress states have on the test results.

Workpackage 3:

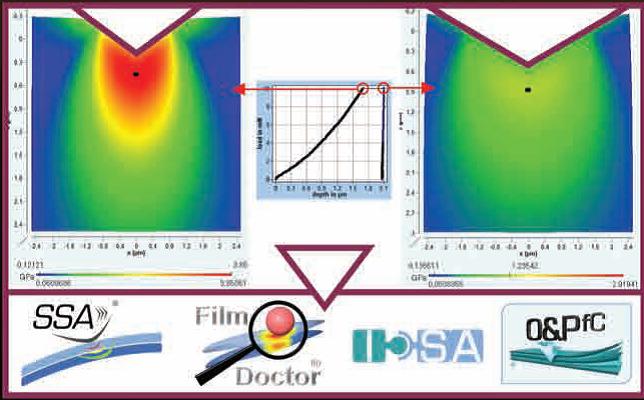

This workpackage will develop and validate algorithms to convert data obtained by indentation creep into simulated values as would be obtained by oscillation methods. Indentation derived results will also be compared to data from acoustics, uniaxial tensile tests and dynamic mechanical analysis (DMA).

Data from independent measurement methods will be used to test the universal applicability of the models and demonstrate that the same property is being measured by all methods. Successful cross-validation between methods will demonstrate a mutually valid material model and open the door to absolute measurement of materials properties traceable to SI units.

Workpackage 4:

Case study to assess creep in the plastic structures used for underground water reservoirs.

The technical work in this project will deliver metrological traceability and valid measurements of mechanical properties of viscous materials to a wide range of industrial sectors. Examples of the industrial relevance of the techniques will be demonstrated through a series of case studies.

More general dissemination of the test procedures will be achieved through ISO standardisation, scientific papers, conference presentations and training courses details of which will appear on this website.