MEMS Microphones

The high volume market of portable electronic consumer products such as mobile phones and notebook computers has been the key driving force behind the research, development and application of MEMS microphone technologies in recent years.

Although MEMS microphone technologies are already available, they are not being exploited for precision noise measurements because of inadequate or indeterminate performances compared to conventional instrumentation grade condenser microphones. The required performance of instrumentation grade MEMS microphones is beyond that achievable with current commercial MEMS microphones. Hence, an important part of the DREAMSys project is to develop high performance novel transducers which will be suitable for precision noise measurement applications.

As the design of DREAMSys is for prolonged outdoor use, the microphone assemblies have been designed to be proof against adverse weather conditions, and powered by rechargeable battery packs in order to run unattended for a duration of more than two weeks.

What are MEMS?

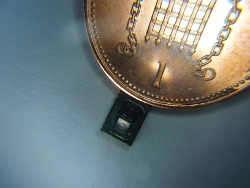

Micro-Electro-Mechanical Systems technology uses techniques developed by the semi-conductor industry to fabricate mechanical structures, often in silicon. Structures such as cantilevers, flexible diaphragms, springs and meshes can be produced in micro-sized packages, and combined with electrical components, to produce a myriad of devices. The MEMS technology is especially suited to the production of microphones, and indeed the vast mobile phone market has driven the development of very low cost microphones, albeit not designed for measurement applications. NPL and QinetiQ are working together to develop measurement grade microphones for use in DREAMSys.