Case Study:

Characterization of low temperature dielectric measurement system

SIQ has worked closely with the University of Nova Gorica (UNG) to improve their system for the determination of the electromagnetic characterization of materials at low cryogenic temperatures and up to 2 MHz in frequency.

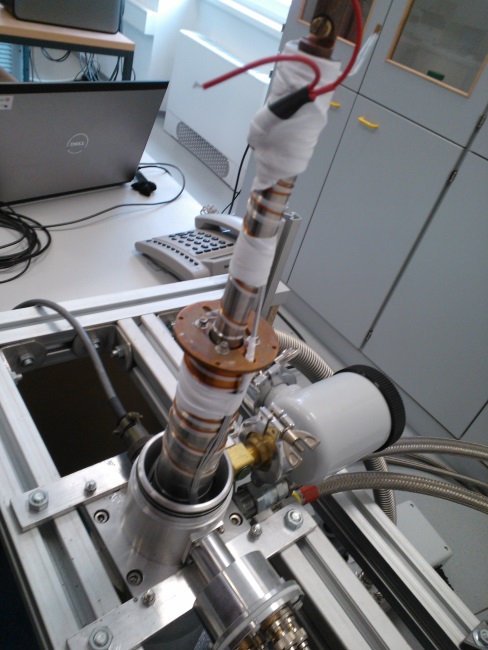

UNG had previously developed its own system for dielectric measurements of materials at low temperatures. It consists of cryogenic system which cools the measuring cell that holds the sample between its electrodes. This cell is enclosed in a cryogenic cylinder in which coolant controls the temperature of the lower part of the cell, which is made of copper. Electrodes are connected to the measuring instrument (a Four-Terminal-Pair (4TP) LCR impedance meter) using four coaxial cables emerging from a special divider box just outside the cell. Between this box and the electrodes there are four thin coaxial cables which then connect individually to the electrodes. These four connections are clamped to the electrodes when the specimens to be measured are placed between the electrodes. Sometimes also magnetic bias is used which is implemented via a permanent magnet placed over the sample.

The Challenge

Various features of this measuring system had never previously been assessed metrologically. In this study, significant influences on measurement were identified to be: (i) the influence of attenuation and phase shifts of the signal in the coaxial cables, both in the divider box and in the thin coaxial cables leading to the electrodes in the cell; (ii) the influence of low temperatures on the measuring system; (iii) the influence of the repeatability of connections between the electrodes and the wires leading into the divider box; and (iv) the influence of the magnetic field used for magnetic bias. Different methods for calibration of the system also had to be investigated, for example the use of Open and Short circuits, and/or reference materials.

The University of Nova Gorica requested help from SIQ in characterizing the system and in making its measurements both reliable and traceable to international standards. Through the EMINDA project SIQ possesses reference materials and other standards and methods which can be used for this kind of characterization. It was also seen that SIQ could help to develop in estimating an Uncertainty Budget for the instrument to allow users to know what the performance of the system is.

The Solution

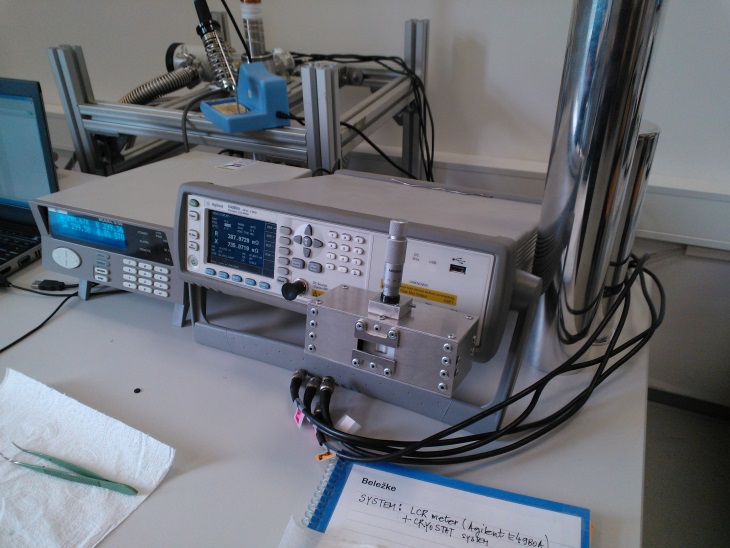

SIQ conducted a characterization of the measuring system using its own standards and reference materials. A number of means of compensation and calibration methods were investigated to identify procedures that can provide the most accurate results and can be implemented relatively quickly before the measurements. The LCR meter used for the measurements was also checked for proper operation and accuracy using impedance standards. The effect of cables was corrected using Short/Open/Load calibration using reference materials as 'Load' standards. The reference material was first measured using the SIQ reference measuring cell connected to the instrumentation normally used at UNG. These values were then used as reference values for calculating corrections for measurements at the end of the cables inside the cryogenic system. A correction sheet has been prepared where corrections at different frequencies are given so that each measurement made with the instrument can be corrected for the effects of the cables. This way SIQ computed the corrections to the UNG system. The results and differences are given in the following table:

| f | Cs_Uncorr | D_Uncorr | Cs_Corr | D_Corr | Δ_Cs | Δ_D | Δ_Cs | Δ_D |

| [kHz] | [pF] | [pF] | [pF] | [%] | [%] | |||

| 5 | 552 | 6,48 | 547 | 6,64 | -5,27 | 0,16 | -1 | 2 |

| 10 | 288 | 6,60 | 289 | 6,67 | 0,98 | 0,06 | 0 | 1 |

| 50 | 84,6 | 5,23 | 85,0 | 5,27 | 0,42 | 0,05 | 0 | 1 |

| 100 | 50,1 | 4,79 | 49,6 | 4,90 | -0,45 | 0,11 | -1 | 2 |

| 500 | 17,4 | 3,24 | 16,5 | 3,48 | -0,97 | 0,23 | -6 | 7 |

| 1000 | 13,5 | 2,22 | 12,5 | 2,43 | -0,98 | 0,21 | -7 | 10 |

Table 1: Example of corrected and uncorrected measurements

Prior to this work, just Open and Short standards and the 2-metre cable compensation built into the LCR instrument was used at UNG, but the latter assumes that the original 2-m cables from the manufacturer are used, which is not the case. These measurements are given in the table as 'Uncorr' while measurements marked 'Corr' are corrected measurements using an Open/Short/Load correction.

The Impact

Prof Dr Matjaž Valant, Head of Materials Research Laboratory at University of Nova Gorica, has many years' experience at the materials research. He commented: "The characterization SIQ made helped us to better understand our system and to make reliable and repeatable measurements using our system". Previously before the system was characterized one could not really know what was being measured: it is now possible to distinguish between the effects of the sample in the cell and the influences of the measurement system itself in the measurement results.

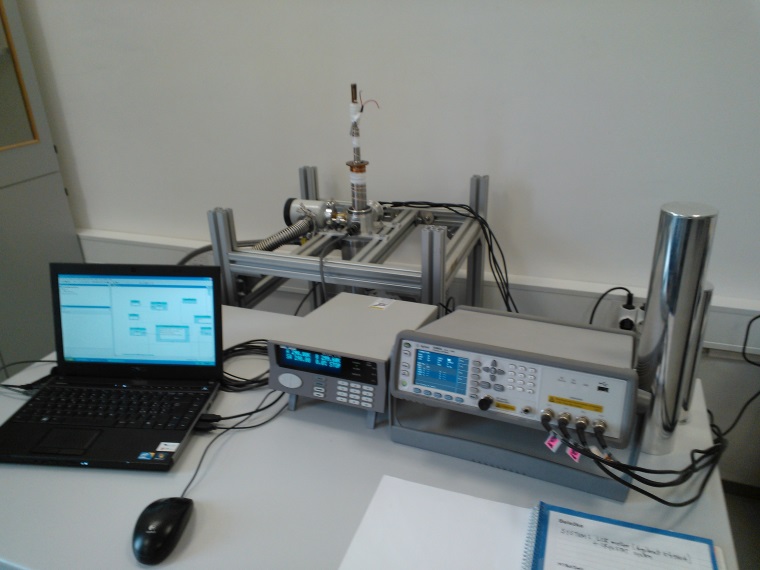

Figure 1: Measuring instrument and PC with cryosystem in the background |

Figure 2: Cryosystem with sample holder at the top |

Figure 3: Detail of the sample holder and cables |

Figure 3: Reference material measured at the front panel |